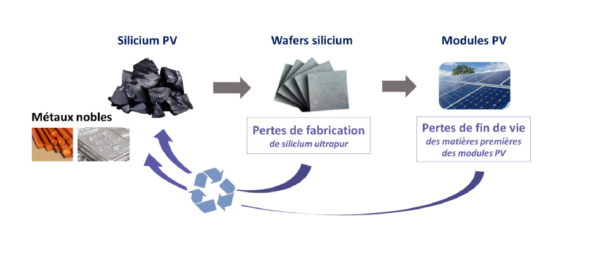

French start-up Rosi Solar has developed an industrial solution claimed to be capable of recovering high purity silicon, silver and copper contained in end-of-life PV modules. The company’s technology is based on a pyrolysis process that makes it possible to isolate the different metals from the cells.

Grenoble-based company Rosi Solar has developed a novel solution for recycling and reusing raw materials from the photovoltaic industry.

In particular, the start-up has set up a thermal and chemical separation process to recover ultra-pure silicon and other metals lost during the production of photovoltaic cells and at the end of the life of solar panels.

Rosi Solar was launched in 2017 and, since then, it has attracted the interest of many companies and institutions that now support it: French environment and energy agency Ademe, the French national investment bank BPIFrance, French environmental services provider Veolia, and European Union programs in particular.

The company’s technology is based on a pyrolysis process that makes it possible to isolate the different metals from the cells. Pyrolysis is generally used for temperature decomposition of organic material in the absence of oxygen. This process is known to provide excellent rate capability and high cycling stability. It is used in the chemical industry to produce ethylene, carbon and chemicals from petroleum, coal and even wood, in addition to producing coke from coal.

Read More: https://www.pv-magazine-australia.com/2022/02/16/new-pv-module-recycling-tech/

Recent Comments